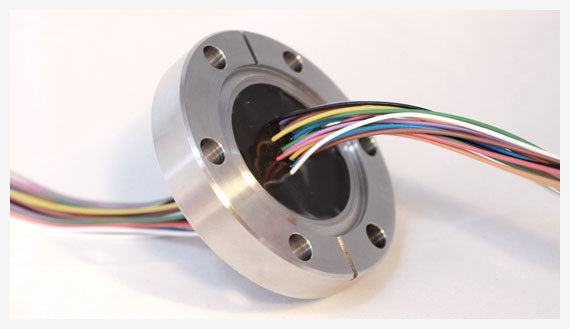

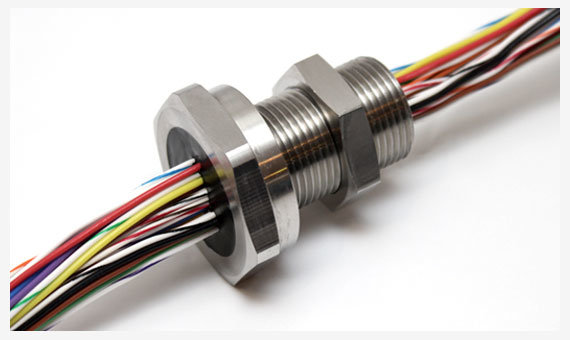

HERMETIC WIRE FEEDTHROUGH

Hermetic bulkhead connectors may be the standard, but they aren’t always the best solution. Hermetically sealed wire feedthroughs offer numerous advantages over off-the-shelf bulkhead connectors including a lower cost, reduced electrical problems, design flexibility, and a longer lifespan.

RHSeals can design and deliver hermetically sealed wire feedthroughs with a shorter lead time than our competitors to help you realize these benefits over traditional connectors.

WHY CHOOSE EPOXY SEALED WIRE FEEDTHROUGHS?

Bulkhead connectors are often used to route data and power in isolated environments. Standard bulkhead connectors may be used to pass wires and cables through the walls of vacuum and pressure chambers, but they are rarely the best solution.

Sealed bulkhead connectors come with unnecessary design constraints and increased costs, and they can trigger electrical issues.

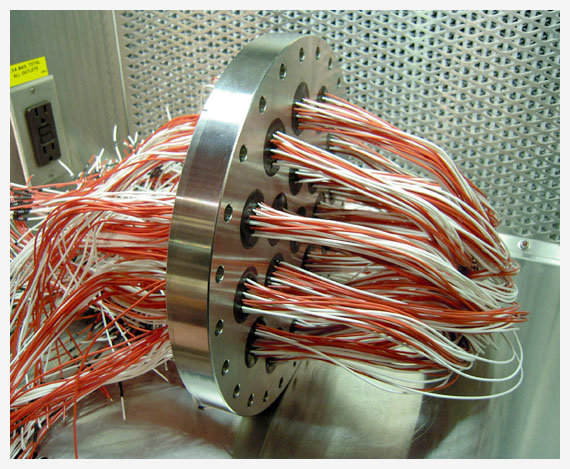

An epoxy sealed wire feedthrough is almost always a better solution if you don’t need a disconnect at the bulkhead. A wire feedthrough that is hermetically sealed with epoxy offers a more flexible solution that saves space and reduces maintenance. A standard bulkhead connector comes with strict limits on the gauge and number of conductors. Most connectors are very limited on the size of pins or the number of pins available, and it can be difficult to find mixed-gauge connectors. These standard bulkheads are also rarely perfect for any specific task, forcing engineers to compromise a design or over-engineer a system’s design to make up for these limitations. A continuous wire feedthrough can have thousands of conductors or just a few connectors, with designs specific to the application’s requirements.

In general, continuous wire feedthroughs save space compared to standard bulkheads. A well-designed wire feedthrough can double the amount of connectors in a given opening. This allows a single feedthrough to combine the signal and power wires from multiple bulkhead connectors. A feedthrough will not protrude like connectors, which provides greater clearance for moving parts.

These feedthroughs pass conductors in a wire harness through a chamber wall with no vacuum or pressure loss. An epoxy sealed wire feedthrough also eliminates issues with voltage drop, contact resistance, and other electrical problems that affect connectors. With epoxy sealing technology, there are no kovar, platinum, or inconel pins like you’d find in glass or ceramic seals; this makes an uninterrupted passage of the wire or cable. Because the conductor through the seal is continuous with no solder terminations, hermetic wire feedthroughs offer reliable electrical performance. Epoxy hermetic seals even allow for the use of different types of conductors and wires in the same feedthrough, adding yet another advantage over traditional connectors.

It’s a common misconception that custom wire feedthroughs are more expensive than standard bulkhead connectors. While this may seem logical, it’s essential to consider the total installed cost of each solution. A single wire feedthrough with one wire harness may replace numerous standard connectors, each with its own harness. A feedthrough can achieve significant savings by reducing the number of wire harnesses that must be designed, produced, and installed.

Wire feedthroughs can also reduce bill-of-materials, simplify the procurement process, and eliminate the high costs of over-engineering systems around bulkhead connectors when standard models cannot match the exact requirements of an application. Replacing even a single glass-to-metal connector with an epoxy sealed wire feedthrough may save about 50%, but the savings will be more dramatic when multiple connectors can be replaced.

While hermetically sealed wire feedthroughs are custom solutions, they come with lower installation costs, reduced maintenance, and better performance than bulkhead connectors.

WHEN SHOULD A WIRE FEEDTHROUGH BE USED?

Because most feedthrough applications are meant to be sealed permanently, an epoxy sealed wire feedthrough is a better solution than a bulkhead connector. In these cases, a robust seal and long-term resistance to mechanical stress without electrical losses should be prioritized over the ability to disconnect the wires.

Common applications that can benefit from a wire feedthrough include military ordinance-controlled applications, medical imaging systems, and voltage electrical switches.

Wire feedthroughs typically have a longer life than standard bulkhead connectors due to the wear and tear on the connector itself. Repeated connecting and disconnecting a pair of connectors reduces the lifespan of the connector. If the disconnect is necessary, sometimes it can be added to the end of a wire feedthrough. As the connector wears, it becomes necessary to continue replacing the bulkhead connector. A wire feedthrough eliminates this wear cycle and lowers the long-term cost.

Continuous feedthroughs can also be used in older systems when retrofitting is necessary. Adding new instrumentation or sensors to an existing chamber can be a time-consuming and difficult task when using standard connectors or when the opening of the chamber wall does not allow additional conductors. A wire feedthrough can be adapted to add more conductors to work with limitations in an existing system.

WHY CHOOSE RHSEALS?

At RHSeals, our wire feedthroughs have been used in every industry in which wire seals are used, including labs, medical facilities, and airport equipment. We test every seal we manufacture with pressure and/or helium leak test as well as hipot and/or continuity testing to ensure every feedthrough is robust and properly wired.

We can seal any gauge wire, including solid and stranded conductors, with no detectable leakage through the wire or insulation. Whether it’s Teflon, PVC, EPDM, XLPE, etc., we can seal cables and wires ranging from a few inches to hundreds of meters. Epoxy sealed wire feedthroughs completely block gas or liquid from leaking through the conductors and any insulation without affecting the electrical characteristics of the cable.

An epoxy hermetically sealed wire feedthrough doesn’t need to be a long-lead item. At RHSeals, we routinely ship custom wire seals with shorter lead times than our competitors can deliver with their Quick Delivery items. If you cannot find the right design from our catalog of more than 500 wire feedthroughs, contact us! Our engineering team excels at designing feedthroughs that can be assembled quickly to your custom wire count and size.

Contact us today to start designing an economical and robust hermetic wire feedthrough that will perfectly match the needs of your application.

VIEW SOME OF OUR

Best Selling PRODUCTS

Check out some of our most popular products. Questions? Call now. We are happy to help.

Custom Hermetic Seals

RHSeals can create a hermetic seal for almost any connector you can find.

Limited Lifetime Warranty

100% of parts go through a rigorous leak, electrical, & visual inspection.

Reliable & Affordable

One stop shop complete wire harnesses, electrically tested with our computer controlled equipment.