THERMOCOUPLE FEEDTHROUGH

Thermocouple vacuum feedthroughs are commonly used for temperature measurements in vacuum environments where using a thermometer wouldn’t be practical or data recording is necessary. Thermocouple pressure feedthroughs are also available for application with pressure chambers. For example, thermocouple feedthroughs are ideal for measuring temperatures in vacuum gauges, gas turbine exhaust, diesel engines, fuel tanks, and lab settings.

A thermocouple feedthrough doesn’t directly measure temperature. Instead, it’s used to calculate temperature through a thermoelectric voltage caused by a temperature difference between two ends of the electrical conductor. A thermocouple vacuum feedthrough uses two different metals that conduct electricity at different rates. On one end of the cable a junction is made joining the two dissimilar metals. This junction of the two dissimilar metals creates a voltage that varies with temperature. A temperature can be determined by measuring the voltage between the two wires opposite end of the junction.

Each metal is insulated from the other except at this junction point, which provides a voltage reading. Without proper insulation of the metals, the reading will be inaccurate. With a thermocouple feedthrough, the thermoelectric voltage generated at the sensing junction is transmitted the entire length of the interconnecting thermocouple alloy or compensating material from inside a chamber to an external instrument.

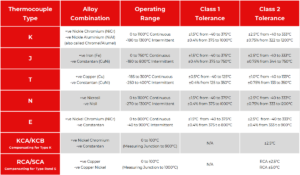

THERMOCOUPLE TYPES

A variety of noble and base metals and alloys can be used to create thermocouple feedthroughs depending on the application. Corrosion resistance, linearity, and high thermoelectric voltage are the most important factors in choosing metals. Common alloys include Chromel (nickel and chrome), constantan (copper and nickel), and Alumel (nickel, manganese, and aluminum).

RHSeals produces thermocouples in many combinations of calibrations or metals. The most common are base metal thermocouples (Types J, K, T, E, and N). We also produce high-temperature thermocouple calibrations. These noble metal thermocouples include Types R, S, C, and GB.

APPLICATIONS

Our thermocouple vacuum feedthroughs are used in a variety of:

- Fuel Tanks

- Aerospace

- Lab Settings

- Gloveboxes

- Vacuum Gauges

- Gas Turbines

- Industrial Equipment

- Power Generation Control

- Semiconductor Equipment

- LED & Solar Processing Equipment

WHY CHOOSE RHSEALS?

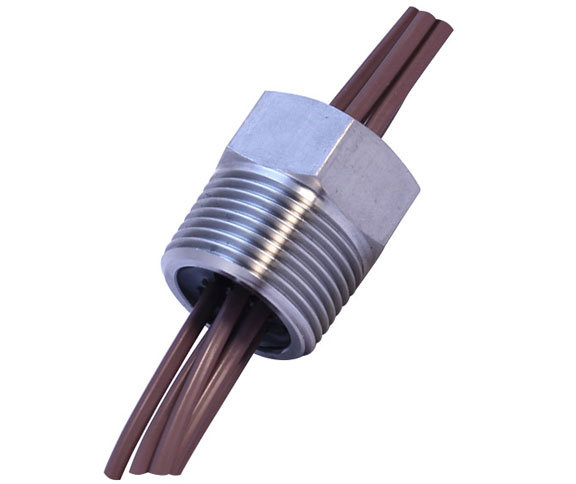

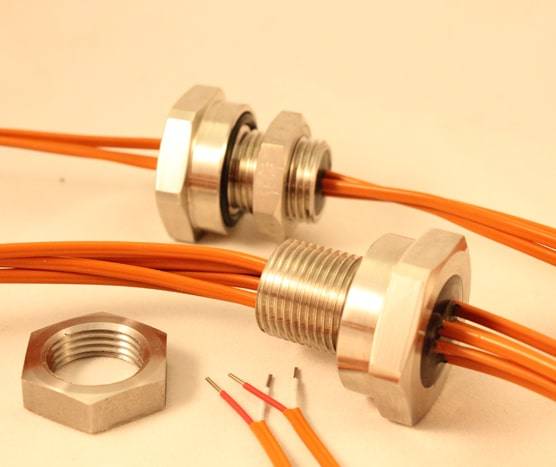

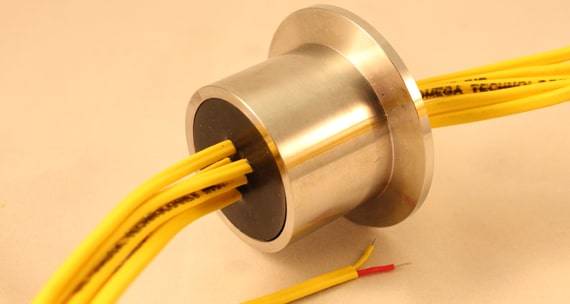

At RHSeals, we produce a variety of hermetically sealed thermocouple feedthroughs. We can make a sealed thermocouple to any length your application requires with technology to seal any stranded or solid conductor thermocouple in any standard insulation material like glass braid, PVC, and Teflon. We can also manufacture many types of thermocouple connectors such as D-sub connectors, standard disconnects, and circular mil-spec connectors.

Every thermocouple vacuum feedthrough built by RHSeals is made with thermocouple contacts and/or wire inside the hermetic seal to reduce errors in your application. Our range of thermocouple feedthroughs are all built to handle extreme conditions while remaining specialized for any task. Our feedthroughs are resistant to mechanical shock failure and vibration with proven reliability.

Most of our thermocouple vacuum feedthroughs are custom, but we also have a variety of stock seals available. Contact RHSeals to discuss a custom pairing for your application.

VIEW SOME OF OUR

STOCK PRODUCTS

Check out some of the products we have in stock. Questions? Call now. We are happy to help.

Custom Hermetic Seals

RHSeals can create a hermetic seal for almost any connector you can find.

Limited Lifetime Warranty

100% of parts go through a rigorous leak, electrical, & visual inspection.

Reliable & Affordable

One stop shop complete wire harnesses, electrically tested with our computer controlled equipment.